The main purpose

Pharmaceutical granulation and coating. Granulation: tablet granules, granules for granules, granules for capsules. Coating: protective layer of granules and pills, color preparation slow release, film, enteric coating. Food granulation and coating. Stir-fried sugar, coffee, cocoa powder, butter powder juice, amino acids, seasonings, puffed food. Pesticides, pigments, dyes, granulation. Dry powder, granule and block materials.

Features

Through powder granulation, fluidity is improved and dust flying is reduced. Improve its solubility through powder granulation. Mixing-granulating-drying is completed in one machine. Using antistatic filter cloth, the equipment is safe to operate. Set pressure relief holes, once an explosion occurs, personnel will not be injured. The equipment has no dead corners, loading and unloading is light and fast, and it is convenient to wash, which conforms to the "GMP" standard. High degree of automation, with program control, analog screen display and other technologies for users to choose.

working principle

The powdery material is put into the closed container of the hopper. Due to the effect of the hot air flow, the powder is suspended in a fluidized circulation to achieve uniform mixing. At the same time, the atomized binder is sprayed into the container to moisten the powder in the container, and the powder is condensed into a loose shape. Small particles, granules, at the same time, due to the hot air stream for efficient drying, the water evaporates continuously, the powder continuously solidifies, and the priming process is repeated to form ideal and uniform microporous spherical particles, which are mixed in the container at one time. Three processes of granulation and drying. Taking the water content and disintegration time of the solid preparation as the inspection indicators, the results were tested by t. Results: When the solid preparation was dried, the boiling drying method was significantly different from the traditional drying method (p0.01).

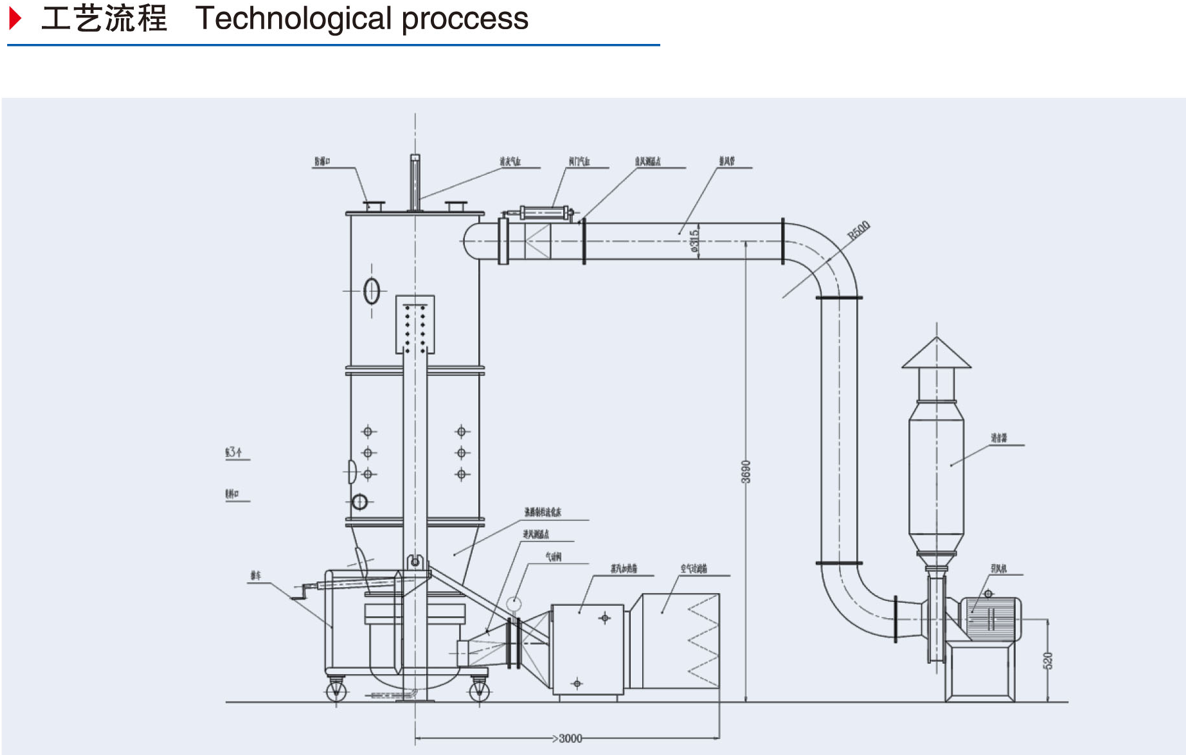

Process flow

1. Material truck 2. Control valve 3. Primary filter 4. Sub-high efficiency filter 5. Heater 6. Material liquid pump 7. Induced draft fan 8. Muffler