Equipment overview

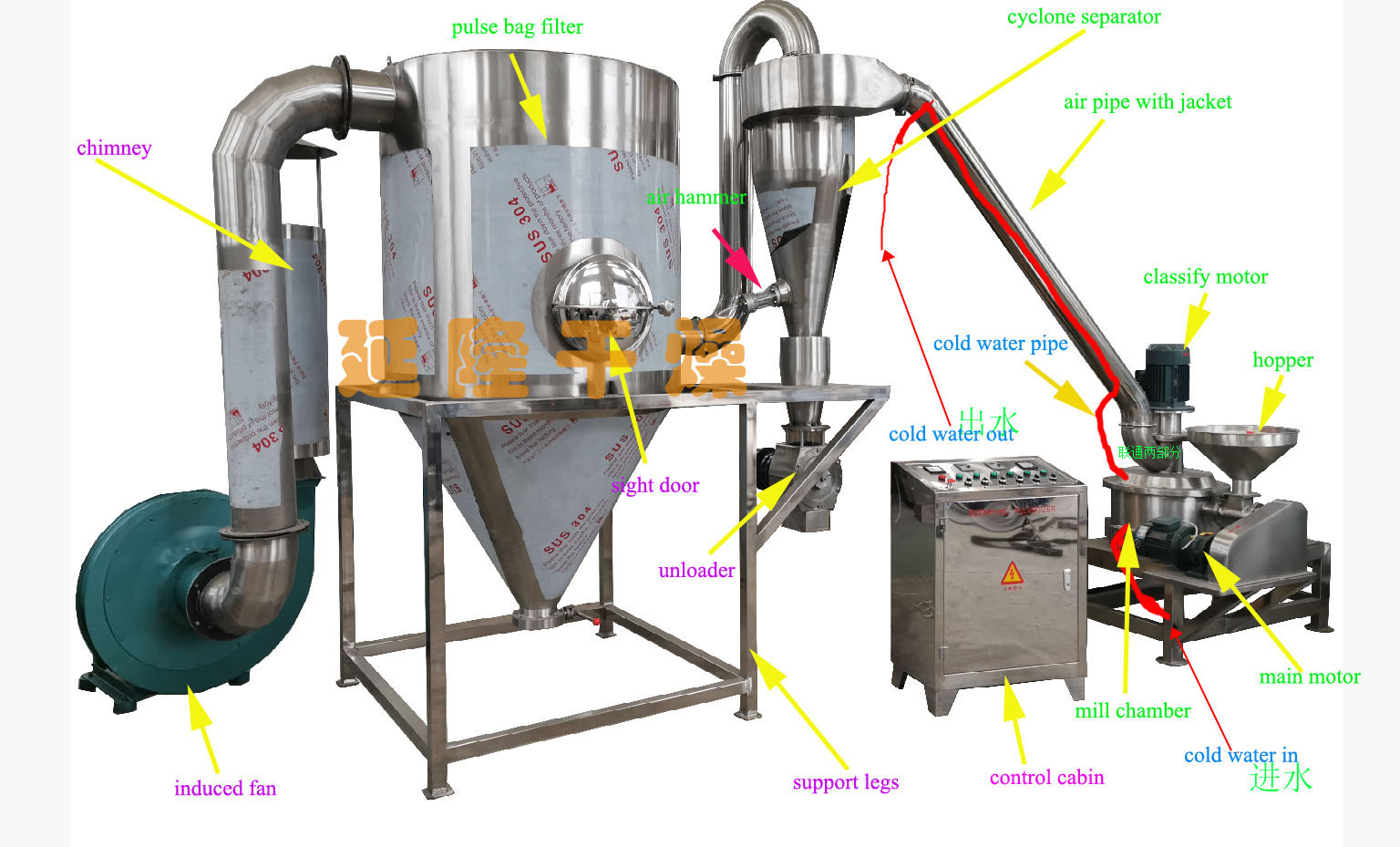

This machine is composed of three parts: main machine, auxiliary machine and electric control box. It has compact design and reasonable structure. It has a winnowing type and no screen. The machine is equipped with a grading mechanism, which can make crushing and grading completed at one time. The negative pressure conveying makes the heat generated in the cavity of the crushing operation continuously discharged, so it is also suitable for the crushing of heat-sensitive materials. This machine has a wide range of applications, the production process is continuous, and the discharge particle size is adjustable; it can handle the crushing and classification of various materials such as chemicals, food, medicine, cosmetics, dyes, resins, and shells. This machine can be designed as The special grinder for white carbon black, sulfur, chitosan (chitin) and other characteristic materials has the advantages of high output and low energy consumption!

The material enters the crushing chamber through the screw conveyor through the material door, and is sheared and crushed by the high-speed rotating blade. The material is transported into the cyclone separator by the method of negative pressure air transportation, and the material is discharged. The dust is filtered by the dust collector through a cloth bag or a filter cartridge. Recycling, there is no dust in the production process, and can improve the utilization rate of materials and reduce enterprise costs.

Scope of application

This machine is widely used in pharmacy, chemical industry, food (for example: Chinese medicine, food, chemical industry, health care, roots, diameter, corn, rice, pepper, pepper, oil wheat, soybean, garlic, star anise, cinnamon, dehydrated vegetables, hawthorn, Dried ginger, sugar, saccharin, grains, dried shrimp skin, pumpkin powder, seasoning) and other industrial materials are crushed.

Model | WFJ-15 | WFJ-20 | WFJ-30 | WFJ-60 |

capacity(Kg/h) | 10-150 | 15-200 | 50-600 | 100-1200 |

Feed size(mm) | <8 | <10 | <12 | <15 |

Discharge size(mesh) | 80-400 | 80-400 | 80-400 | 80-400 |

Power(kw) | 13.5 | 21 | 46 | 84 |

Speed(r/min) | 6000 | 5400 | 3800 | 2900 |

Size(mm) | 4000*1400*2700 | 4700*1400*2800 | 6700*1600*3200 | 7500*2000*3400 |

Weight(kg) | 1100 | 1400 | 2300 | 3800 |