The universal pulverizer utilizes the high-speed relative movement of the movable toothed disk and the fixed toothed disk to crush the pulverized objects through the combined effects of tooth impact, friction and material impact. This machine is simple in structure, sturdy, stable in operation, and has good crushing effect. The crushed material can be directly discharged from the main machine's grinding chamber, and the particle size can be obtained by changing mesh screens with different apertures. In addition, the machine is all stainless steel. The inner walls of the casing are all machined to achieve a smooth surface, which has changed the rough and powder accumulation on the inner walls of the previous models, and made the production of medicines, foods, and chemicals more in line with national standards and GMP requirements.

The universal crusher is suitable for industries such as pharmacy, chemical industry, metallurgy, food, construction and so on. For processing hard and difficult to pulverize materials, including pulverizing plastics, copper wires, Chinese herbal medicines, rubber, etc., it can also be used as a supporting equipment for the pre-processing of micro-pulverizers and ultra-fine pulverizers. The powder chamber adopts a fully enclosed sound-absorbing structure, which can effectively reduce working noise. The machine is equipped with a cooling device to reduce the temperature of the machine and work more smoothly. The motor speed of the machine is 5000 rpm. This machine is made of Icr18Ni9Ti stainless steel material, which has strong wear-resistance and corrosion resistance characteristics, and is suitable for processing advanced and corrosive materials. This machine adopts the impact crushing method. After the material enters the crushing chamber, it is impacted by six movable hammers rotating at a high speed. The ring gear and the material collide with each other to be crushed. Powder bag, leaving no residue. It has the advantages of high efficiency, low noise, reliable work performance and product quality, safe operation, hygienic medicine and low loss.

The material of the universal pulverizer is fed into the pulverizing chamber from the feed hopper. After the impact of the blade and the knife seat, the rotating knife and the fixed knife are sheared and crushed at the same time. Due to the action of the rotating centrifugal force, the material automatically flows out from the outlet.

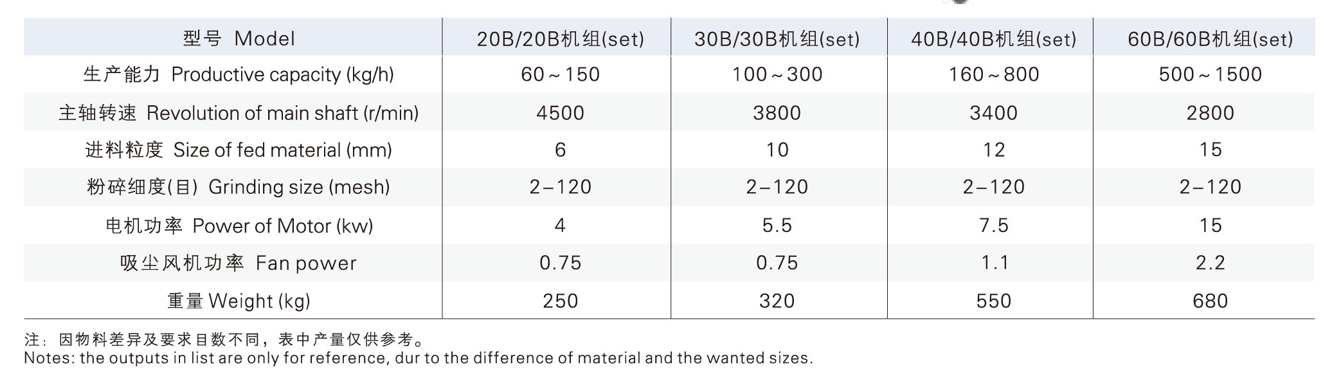

Note: Due to the large difference in materials, the output varies greatly.

Pin mill blade

Pin mill blade in fact can be pin type, hammer type

The structure of the universal crusher

According to dust removal requirements, various structures can be manufactured.

1. Single machine type

2. As shown in the picture, it is recommended to remove dust, using breathing cloth bags and powder collecting bags, which is simple, effective and low-cost.

3. cabinet type, discharge port inside the machine

4. Connect the cyclone separator for continuous production.

5. The main machine can be also combined with cyclone and bag filter to become a continuous production line and control the dust very well

Technical parameter