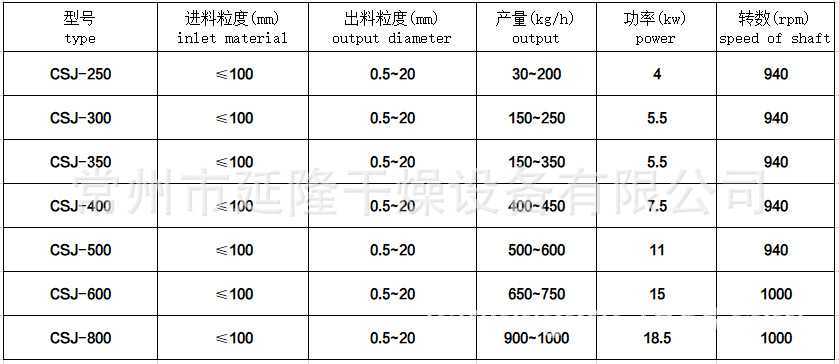

Stainless steel CSJ type coarse crusher Chinese medicinal material powerful crusher Main purpose of medicinal material crusher

CSJ series coarse crusher is suitable for pharmaceutical, chemical, metallurgical, food, construction and other industries. For processing hard and difficult to pulverize materials, including pulverizing plastics, steel wires, etc., the composite rock chip grinder can also be used as a supporting equipment for the pre-process of micro-pulverization.

Features

The CSJ series coarse crusher adopts a vertical crushing mechanism, which is not restricted by the viscosity, hardness, and softness of the material, and can have a better crushing effect on any material.

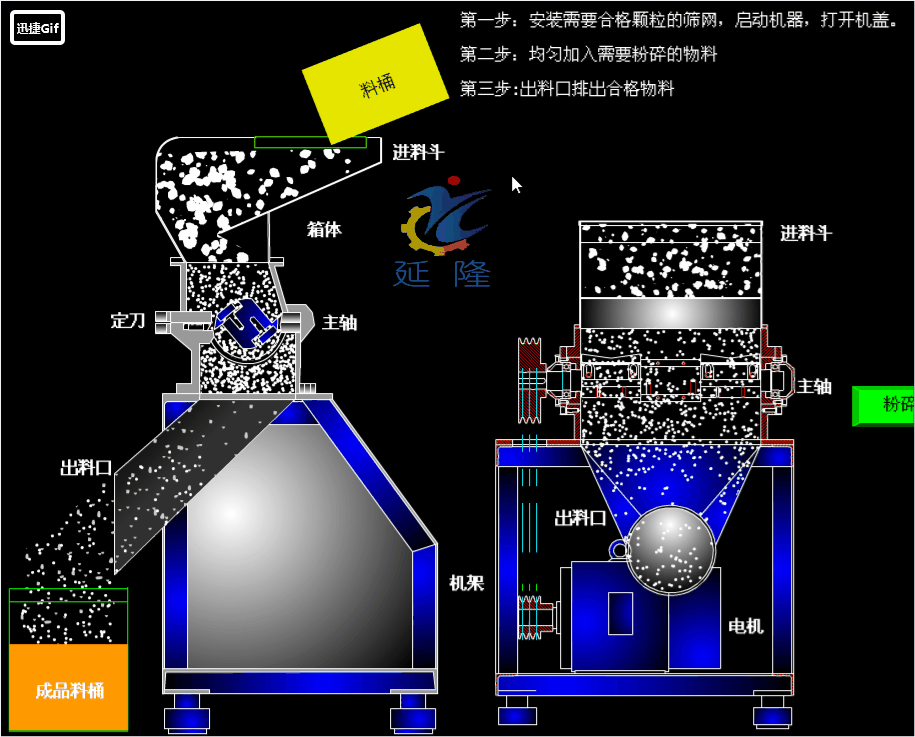

working principle

The CSJ series coarse crusher is fed into the crushing chamber from the feed hopper. The rotating knife and the fixed knife shear and crush at the same time through the impact of the knife blade and the knife seat, and the material automatically flows to the outlet due to the effect of the placed centrifugal force.

Product advantages

CSJ coarse crusher combines advanced experience in domestic and foreign industries to transform and produce new equipment. It has the advantages of light weight, low loss, excellent blade materials, long service life, and convenient cleaning.

★ The appearance of the machine is beautiful and generous, the color matching is coordinated, and the paint is firm.

★ The inlet hopper, crushing chamber and screen hopper are of separate design, easy to load and unload.

★ Buffer room feed and imported vertical curtain design to avoid material splashing.

★ The front and back walls of the crushing chamber adopt double-layer sound insulation with low noise.

★ The pulley is equipped with a protective cover, which is safe and reliable.

★ Equipped with cleaning safety switch.

★ The motor is equipped with an overload protection device and a power supply interlocking protection system.

It is suitable for broken rhizomes of Chinese herbal medicines and fragile broken plastics. Corresponding sieve plates can be replaced to adjust the particle size. The blade gap can be adjusted, and it can also crush various plastic waste products such as calendered film, flakes, and thin plates.