The V-type mixer series products are high-efficiency asymmetric mixers, which are suitable for mixing powder or granular materials in the chemical, food, pharmaceutical, feed, ceramic, metallurgical and other industries. The machine has a reasonable structure, simple operation, airtight operation, convenient feeding and discharging, and the cylinder (manual or vacuum feeding) is made of stainless steel, which is easy to clean. It is one of the basic equipment of the enterprise. Suitable for pharmacy and chemical industry

Agency presentation

This machine can mix dry powder and granular materials of food.

The mixing barrel of this machine has a unique structure, uniform mixing, high efficiency, and no material accumulation. The whole machine is simple in structure and easy to operate. The outer surface and the material contact part are made of high-quality stainless steel, which is beautiful in appearance and easy to maintain and clean.

The V-type mixer series products are high-efficiency asymmetric mixers, which are suitable for mixing powder or granular materials in the chemical, food, pharmaceutical, feed, ceramic, metallurgical and other industries. The machine has a reasonable structure, simple operation, airtight operation, convenient feeding and discharging, and the cylinder (manual or vacuum feeding) is made of stainless steel, which is easy to clean. It is one of the basic equipment of the enterprise.

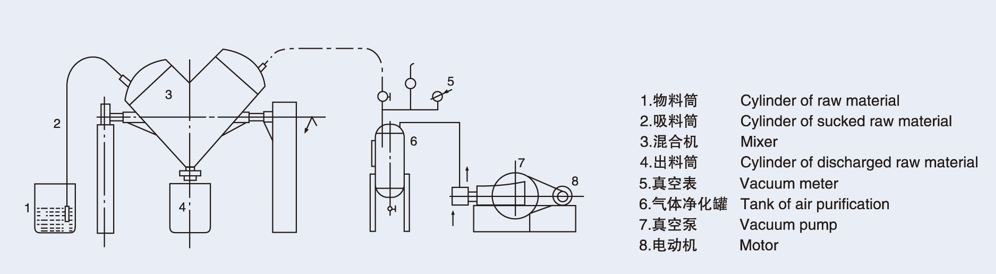

Machine principle and structure

One end of the machine is equipped with a motor and a reducer. The motor power is transmitted to the reducer through a belt, and the reducer is transmitted to the V-shaped barrel through a coupling. Make the V-shaped barrel run continuously to drive the materials in the barrel to mix up, down, left and right in the barrel.

Purpose

It is suitable for the mixing of powders with good material flowability and small differences in physical properties, as well as the mixing of materials with low mixing requirements and short mixing times. Because the material in the V-shaped mixing container flows smoothly, it will not damage the original shape of the material. Therefore, the V-type mixer is also suitable for the mixing of granular materials that are easy to break and wear, or the mixing of finer powder, block, and materials containing a certain amount of water. It is widely used in the pharmaceutical, chemical, and food industries.