working principle

Roller scraper dryer is an internal heating conduction type rotating continuous drying equipment. The rotating drum passes through its lower trough, and adheres to a thick material film. The heat is transported to the inner wall of the drum through the pipe, transferred to the outer wall of the drum, and then transferred to the feeding film, so that the moisture in the material film is evaporated, dehumidified, and dehumidified. The moisture-containing material is dried. The dried material is shoveled away from the drum by the scraper installed on the surface of the drum, to the screw conveyor placed under the scraper, and the dried material is collected and packaged through the screw conveyor.

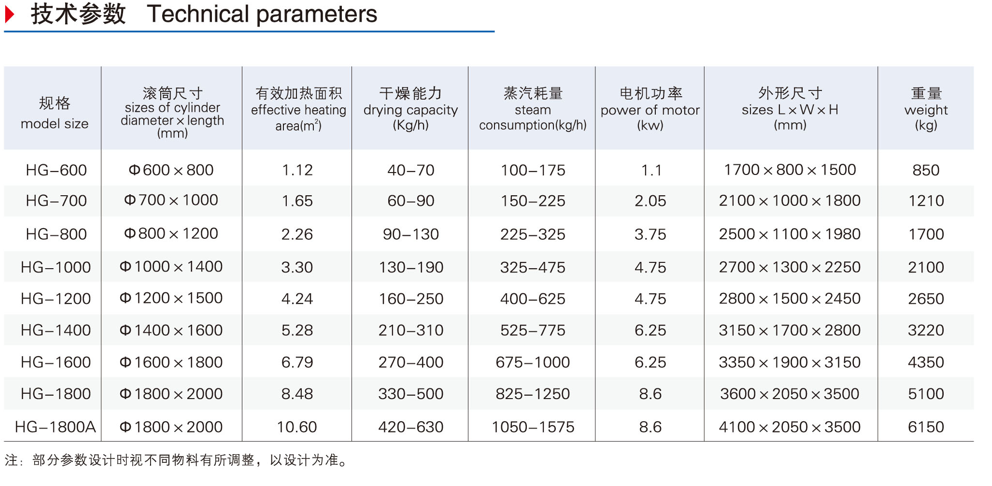

Performance characteristics of HG series (single drum and double drum) rotary drum scraper dryer

◎High thermal efficiency. Because the heat transfer mechanism of the drum dryer is heat conduction, the direction of heat transfer remains the same throughout the operation cycle. Except for cover heat dissipation and heat radiation loss, the rest of the heat is all used for the evaporation of the moisture content of the tube material film, and the thermal efficiency can reach 70%. -80%.

◎Great operating flexibility and wide applicability. Many drying factors of the drum dryer can be adjusted. Such as the concentration of the feed material, the thickness of the coating material film, the temperature of the heating medium, and the rotation speed of the drum, etc., can change the drying efficiency of the drum dryer, and many factors are not related to each other. This brings great convenience to the drum drying operation, so that it can adapt to the drying of a variety of materials and the requirements of different yields.

◎Short drying time. The drying cycle of materials is generally only 10-300 seconds, which is suitable for heat-sensitive materials. If the drum dryer is installed in a vacuum, it can be operated under reduced pressure.

◎High drying rate. Because the material film applied by the paint on the cylinder wall is very thin, generally 0.3-1.5mm, and the heat and mass transfer directions are consistent, the surface of the material film can maintain an evaporation strength of 20-70kg.H2O/m2.h.

Install

The installation of this machine is arranged according to the general drawing, the ground should be flat, pressure gauge and safety valve should be installed at the steam pipe inlet, and the steam inlet flange connection should be firm.

Adapt to materials

◎Suitable for drying liquid or more viscous materials in the chemical, dye, pharmaceutical, food, metallurgical and other industries.