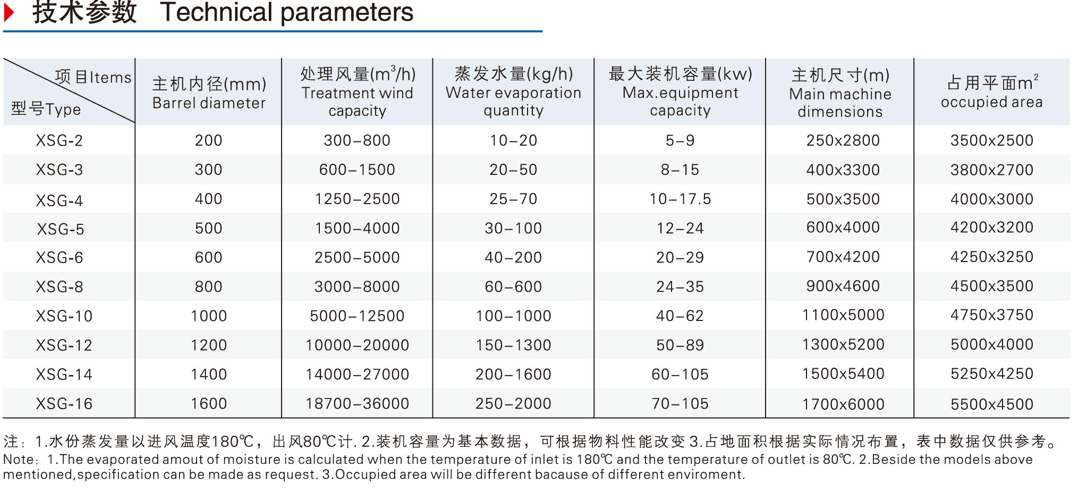

Product overview: XSG series rotary flash dryer is a tangential hot air into the bottom of the dryer, driven by the agitator to form a powerful rotating wind field. Paste material enters the dryer from the screw feeder. Under the strong action of the high-speed rotating stirring blade, the material is dispersed under the action of impact, friction and shearing force. The block material is quickly crushed, fully contacted with hot air, and heated. ,dry.

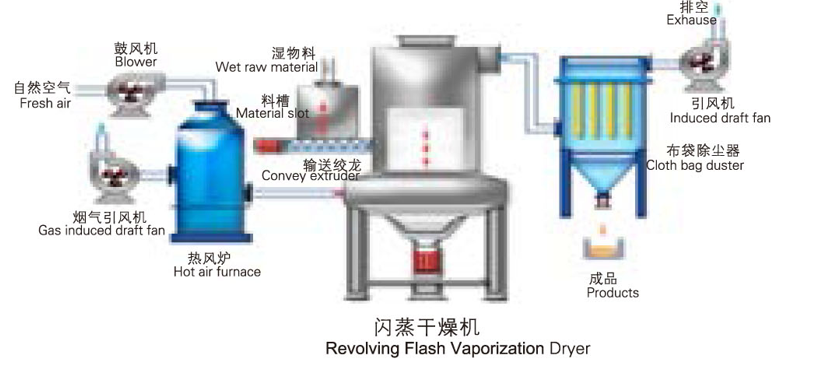

working principle

The hot air enters the bottom of the dryer tangentially, and forms a powerful rotating wind field driven by the agitator. Paste material enters the dryer from the screw feeder. Under the strong action of the high-speed rotating stirring blade, the material is dispersed under the action of impact, friction and shearing force. The block material is quickly crushed, fully contacted with hot air, and heated. ,dry. The dried material after dehydration rises with the hot air flow, the grading ring traps large particles, and the small particles are discharged out of the dryer from the center of the ring and recovered by the cyclone separator and dust collector. The incomplete or large materials are thrown to the wall by centrifugal force. , And fall to the bottom to be crushed and dried.

Performance characteristics

◎The organic combination of swirling, fluidization, spouting and crushing classification technology.

◎Compact equipment, small size, high production efficiency, continuous production, realizing "small equipment, large production".

◎High drying strength, low energy consumption and high thermal efficiency.

◎The material residence time is short, the finished product is of good quality, and it can be used for drying heat-sensitive materials.

◎Negative pressure or micro-negative pressure operation, good airtightness, high efficiency, eliminating environmental pollution.

Adapt to materials

Organic matter: Atrazine (pesticides), lauric acid, benzoic acid, benzoic acid, bactericide,

Sodium oxalate, cellulose acetate, organic pigments, etc.

Dyes: Anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various couples

Nitrogen dye intermediates.

Inorganic substances: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide,

Various metal hydroxides, various heavy metal salts, synthetic cryolite, etc.

Food: Soy protein, gelatinized starch, wine tank, wheat sugar, wheat starch, etc.