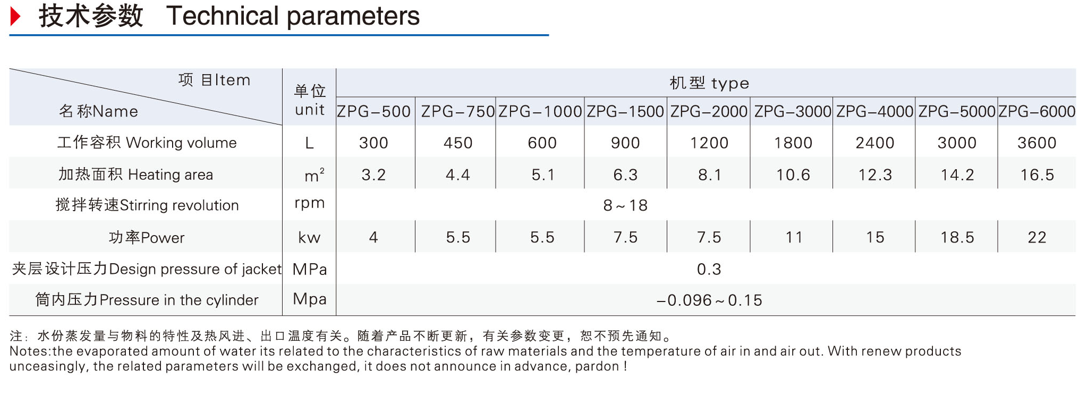

working principle

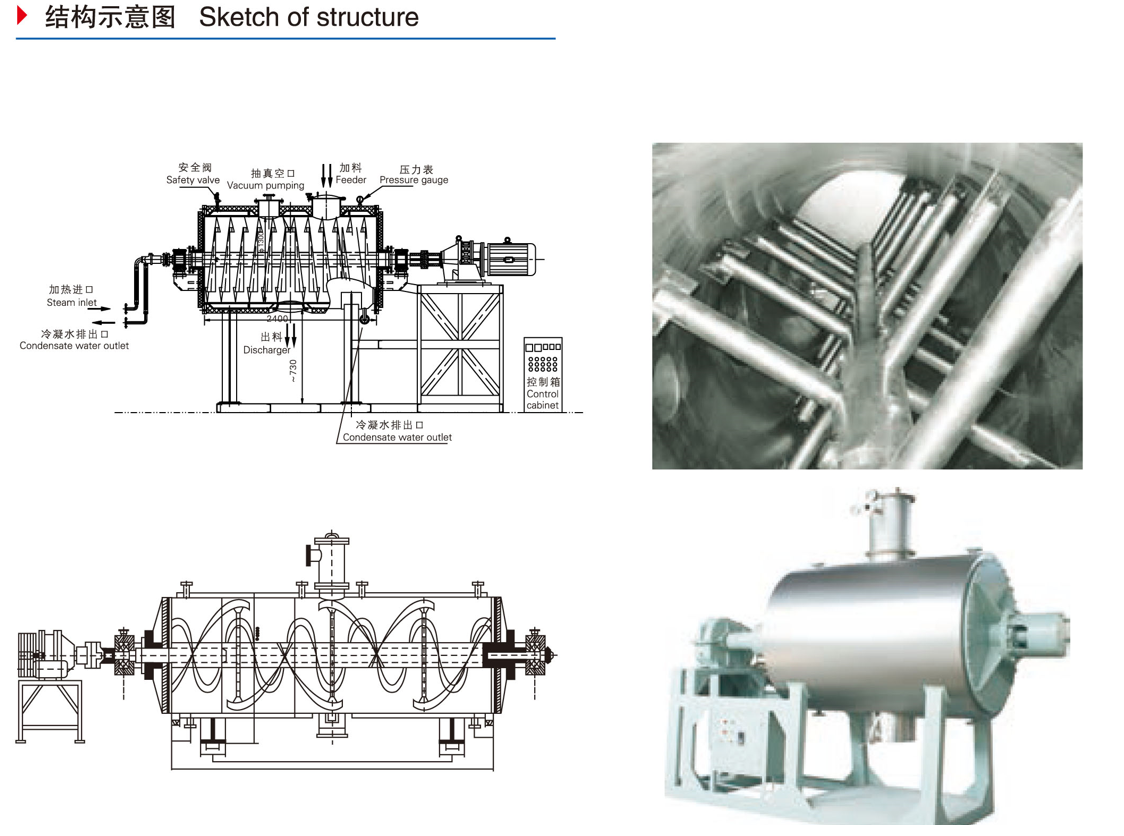

This machine is a novel horizontal batch vacuum drying equipment. The wet material is evaporated by conduction, and a scraper stirrer is equipped to continuously remove the material on the hot surface, and moves in the container to form a circulating flow. After the water evaporates, it is pumped out by the vacuum pump. .

The vacuum rake drying device uses a heating jacket and a hollow rake arm to indirectly heat the material and exhaust it under high vacuum, so it is particularly suitable for materials that are not resistant to high temperatures, are easily oxidized at high temperatures, or are prone to generate powder when dried, and The drying process of the materials that must be recovered by the steam removed during the drying process. The moisture content of the inlet of the material to be dried in the vacuum rake dryer reaches 90%, and the lowest is only 15%. The material to be dried can be slurry, paste, granular, powder or fibrous.

The dried material is added from the middle of the upper part of the shell. Under the stirring of the continuously rotating rake teeth, the surface is continuously updated when the material contacts the shell wall. The dried material is indirectly heated by steam or hot water, so that the material The water vaporizes, and the vaporized water is pumped away in time by the vacuum pump... Due to the high vacuum degree of the drying operation, generally in the range of 400-700mmHg, the water vapor pressure on the surface of the material to be dried is much greater than the water vapor pressure in the evaporation space in the dryer housing, which is beneficial to the discharge of the moisture and surface moisture in the dried material. Conducive to the movement of the moisture of the material being dried, to achieve the purpose of drying.

Performance characteristics

◎This machine adopts large-area interlayer heating method, with large heat transfer surface and high thermal efficiency.

◎This machine is equipped with stirring to make the material form a continuous circulation state in the cylinder, which further improves the uniformity of the heating of the material.

◎This machine is equipped with stirring, so that it can smoothly dry slurry, paste, and paste materials.

Adapt to materials

◎Dry the following materials in the pharmaceutical, food, chemical and other industries:

◎Suitable for slurry, paste and powder materials;

◎ Heat sensitive materials requiring low temperature drying;

◎Easily oxidized, explosive, strongly irritating, highly toxic materials;

◎Materials requiring recovery of organic solvents.