Vertical fluid bed dryer

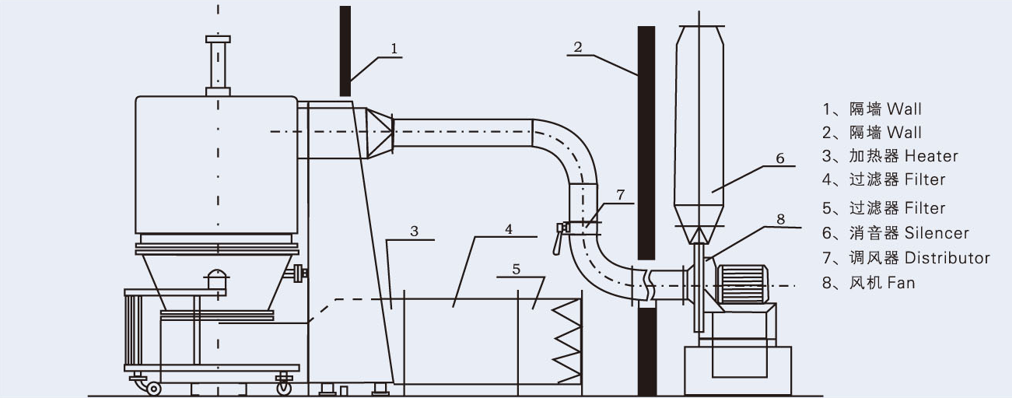

Fluidized bed dryer is a kind of drying equipment, also known as fluidized bed, which is generally composed of heater, fluidized bed host, cyclone separator, bag filter, induced draft fan, and operating table. Depending on the nature of the material, cyclone separator or bag filter can be selected as required.

Principle

Boiling drying is also called fluidized bed drying. It uses hot air flow to suspend wet particles. The fluidized boiling makes the material heat exchange. The hot air takes away the evaporated moisture or organic solvent. It uses hot air flow to carry out the material. The air-solid two-phase suspension contact method of mass heat transfer achieves the purpose of drying the wet particles. Fluidized bed drying technology involves two mutual processes of heat transfer and mass transfer. In the convection drying process, the hot air transfers heat energy to the surface of the material through contact with the wet material, and then transfers the heat from the surface to the inside of the material. This is a heat transfer process; when the wet material is heated, the surface moisture is first vaporized, and the internal moisture It diffuses to the surface of the material in liquid or gaseous state, and continuously vaporizes into the air, so that the moisture of the material is gradually reduced, and the drying is completed. This is a mass transfer process.

After heating and purification, the air is introduced from the lower part of the GFG series high-efficiency boiling dryer by an induced draft fan, and passes through the perforated mesh plate of the hopper. In the working chamber, fluidization is formed by the action of stirring and negative pressure, the moisture is quickly evaporated and then taken away with the exhaust gas, and the material is quickly dried.

Features

◆The fluidized bed of GFG series high-efficiency boiling dryer is circular structure to avoid dead corners

◆The bed is equipped with stirring to avoid the lump of wet materials and the formation of channeling during the drying process

◆GFG series high-efficiency boiling dryer top-mounted bag filter is antistatic special fiber, safe to operate

◆Tipping the material, convenient, rapid and thorough

◆Seal negative pressure operation, designed according to GMP standard

◆GFG series high-efficiency boiling dryer can also be designed and manufactured for automatic feeding and discharging according to requirements

Application range

※Drying wet granular and powdery materials in the fields of medicine, food, feed, chemical industry, etc.

※Screw extrusion pellets, swing pellets, high-speed mixing pellets

※Large particles, small blocks, viscous blocks and granular materials

※Materials that change in volume during drying, such as milled taro, acrylamide, etc.