In recent years, my country's traditional Chinese medicine extract drying technology has made significant progress, and advanced extract drying technology and equipment have been promoted to a certain extent, but the research on drying process optimization and equipment improvement still urgently needs to be strengthened. Yanlong drying is realistically based on the development status of traditional Chinese medicine extract drying technology, and based on the principle, equipment status and technical characteristics of common drying technologies such as box drying, spray drying, and vacuum drying, it analyzes its different drying methods for traditional Chinese medicine soaking. The advantages and disadvantages of ointment drying, and summarized the reasonable selection of appropriate drying methods according to the characteristics of different Chinese medicines in order to improve the quality of the finished Chinese medicine extracts. This project focuses on the spray drying project of traditional Chinese medicine extract. The high-speed centrifugal spray device for traditional Chinese medicine extract is the application of centrifugal spray drying technology in the drying of specific materials. Full contact, complete instant drying, forming a drying device for powdered products. The drying equipment is a spray dryer specially used to solve traditional Chinese medicine extracts and plant extracts. It effectively solves many problems in the drying of traditional Chinese medicine extracts by the original LPG high-speed spray dryer.

Advantages:

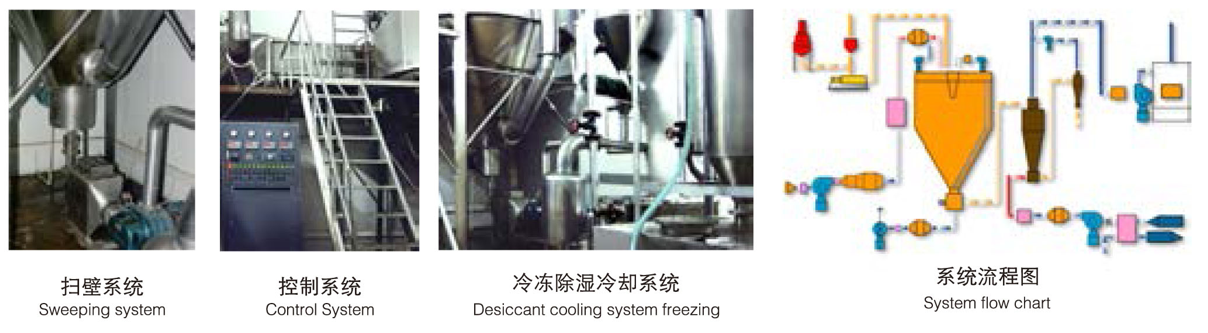

1. In order to prevent sticky walls in the physical sciences, the equipment is equipped with air sweeping wall and tower wall jacket cooling structure to effectively prevent the sticky wall coking of the product. Improve product quality and yield.

2. Unique finished product cold air centralized feeding system, which separates the dried finished product from the hot and humid air in the system in time to avoid the possibility of moisture absorption and moisture regaining of the finished product.

3. The air entering the dryer adopts three-stage air purification, so that the inlet air reaches the 300,000-level requirement;

4. The quick-opening punching device is adopted, which is suitable for the production requirements of multiple varieties;

5. Material collection adopts two-stage cyclone dust removal device or one-stage cyclone dust removal + wet dust collector;

6. The volume and configuration of the spray tower are adjusted for suitability according to the nature of the physical sciences to make it more practical;

7, PLC control can be selected, program control system screen display;

8. The design and manufacture of the entire drying system meets the requirements of GMP;